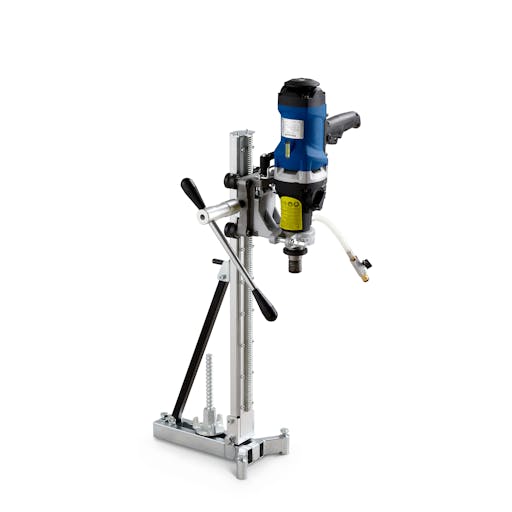

Diamond Core Drills are ideal for drilling both small and large diameter holes in masonry and brickwork. These powerful machines have a variable 3 speed gearbox and are effective with diamond cores up to 160mm.

Diamond core drilling allows accurate the operator to drill accurate holes through nearly all materials, meaning that our heavy duty diamond core drill is a fantastic piece of equipment to hire for your construction site.

Our heavy duty Diamond Core Drill has 10% more input to output ratio than other diamond core drill motors in the construction industry. The power of these Diamond Core Drills are unmatched.

In addition, these Diamond Core Drills produce more speed and has 20% faster diamond core drilling than other professional Diamond Core drill motors available for hire.

Features

- Overload warning system that lowers the voltage and stops the motor once the load reaches overload conditions

- Equipped with a mechanical clutch to protect the operator and machine from excessive torque forces

- Intelligent Power Management (IPM) System to manage the volume of power entering the motor

- Ergonomic handle and extra front handle for extra support and control during use

- Improved cooling and increased durability due to its all metal construction

- Trigger switch to activate the electric motor and control drill speed

- 2 levels built into the motor ensures easy levelling for the us

- Tubular spirit level for increased operator accuracy

- Side handle assy for increased operator control

- Bulls eye level to control horizontal positioning

- Gear selector and variable 3 speed gearbox

- Extension bars and adapters available

- Water feed valve and adapter head

- Compatible with wet core bits only

- Lock button for health and safety

- Quick releasing water coupling

- Spindle 1-¼”UNC & ½”BSP

- Side handle lock screw

- Will take up to 152mm

- Vacuum adapter head

How to use

- Water is a basic requirement for diamond core drilling. The water serves as a coolant to avoid the working surface at the tip of the bit from overheating.

- When the diamond bit becomes overheated, both the bond matrix and even the diamonds break down. The most frequent cause of diamond core bit damage is caused by drilling without enough coolant water.

- Water should always be used to cool and lubricate the bit and to flush out abrasive particles formed while drilling. Never use this machine without water feed.

- To connect the water supply. Attach the quick-release water coupling to a water hose. Never allow water to enter the motor.

- When drilling by hand, always hold the drill in a position where you can resist the twisting forces. Never operate without the side handle tightly in place.

- Select the desired gear range by turning the gear selector either clockwise or counter clockwise

into the desired gear. It will usually be necessary to turn the spindle by hand a little to get it to

shift all the way

- Never lock the switch on when drilling hand-held. Only lock the switch on when mounted to a rig.

- There are 3 speed ranges to suit the bit size and work piece hardness. Choose the slowest speed for large diameter bits and hard materials. If when cutting the bit stalls repeatedly, then you must change to a lower gear. If you are already in the lowest gear and the bit stalls repeatedly, then you are using the machine over its maximum capacity.

| Option | Weight | Vibration | Fitting | Power | Noise | Capacity |

|---|---|---|---|---|---|---|

| Option: 110V | Weight: 6.4kg | Vibration: 1.5 m/s2 | Fitting: 1.25" BSP Thread | Power: 110V | Noise: 97 dB | Capacity: 152mm |